Products & Applications

PRODUCTSApplication Scheme

Location Position:Home > Products & ApplicationsApplication of intelligent lighting in automatic management of large warehouse

Control mode: infrared induction + illuminance automatic control, computer remote centralized control

Modern large factory warehouse area is wide, span is large, many zoning, lighting management if the use of traditional manual control will cause the control difficulty, management is not in place, the increase of labor costs, if the introduction of intelligent lighting control system can easily achieve large warehouse lighting automation, network control and management. Maximize energy savings and reduce labor costs.

From the large workshop warehouse covers a large area and the characteristics of many regional divisions, we can know that the lighting of the warehouse only needs to be lit when someone enters the warehouse, and only when the natural lighting cannot meet the illumination requirements can the light be lit, even if someone enters the natural lighting completely meet the requirements. At the same time, the number of lights can be selected according to different natural lighting, in order to meet the premise of the use of illumination under the maximum energy saving.

Step 1: Demand

1.1. Set according to the external lighting intensity. The lighting in the warehouse can be adjusted from 0%, 25%, 50%, 75% and 100%. Make sure the lighting can be 0% in sufficient natural light.

1.2. According to the activity of people in a certain area and combined with the intensity of light, control the lighting of the area. There are 25 motion and light intensity sensors.

1.3 In the intelligent control mode, once a certain area is lit up, if the lighting condition is not met, it should be able to delay for a period of time (such as 20-40 minutes, adjustable) before extinguishing.

1.4 Can be partitioned for manual control, can also be a key to open or close.

2. Project analysis

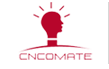

2.2.1 Warehouse partitioning and lighting grouping

A warehouse is about 18,000 square meters, which is divided into 3*1 zones according to the requirements of fire protection zones. The two warehouses have 6 zones in total, A-F six zones, and four groups of lighting control shall be set up in these six zones according to different brightness. According to the electrical circuit design, 24 control circuits are designed for each zone. One warehouse has 72 loops. According to uniform distribution, the power of traditional lamp is about 1.3KW for each loop, and the power of LED lamp is about 0.6KW.

The lamps in each area are evenly distributed into four groups, each group of 6 circuits, each group of power about 7.8KW and 3.6KW.

In addition to the two warehouse is divided into six control zone, otherwise it can realize the switch control of 13 districts (G/H/K/L/M/N/O/P/Q/R/S/T/U).

2.2.2 Sensor layout

Human body sensor and light intensity sensor are arranged at the red star in the figure. There are 25 sensors in total.

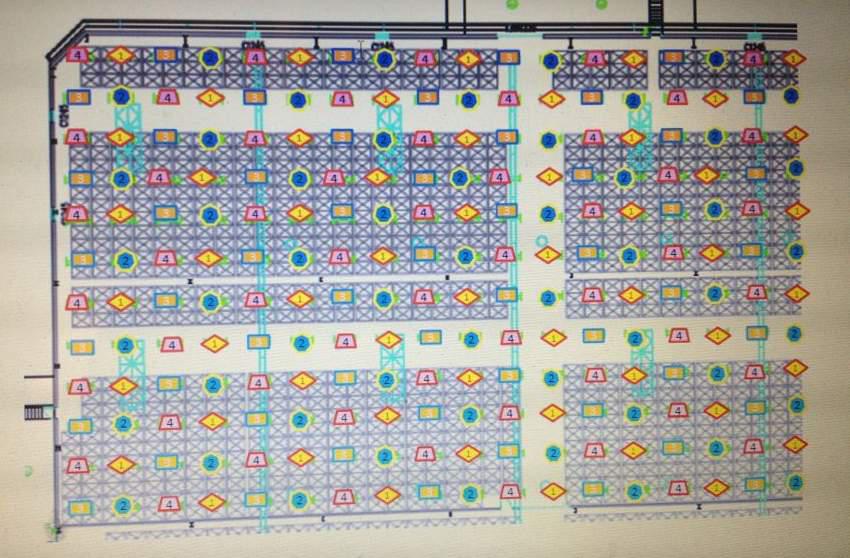

3. Program flow chart

4. Configure the system

A warehouse is divided into 3*1 districts, two warehouses total 6 districts.

One area adopts a 6-channel 16A controller, in which 4 channels are used to control the four groups of lights respectively, and two channels are used for backup. The control power is 220V*17=3.7KW. The power of this group of lights is 7.8KW for traditional lights and 3.6KW for LED lights. For safety, it is not recommended that the controller directly control the lighting circuit, but that the AC contactor be used to control the lighting circuit.

Two additional controllers are added to control the 16 areas controlled by the switch.